Here are 3 words you probably haven’t heard, but are critical to your Lean journey.

YOKOTEN HANSEI HEIJUNKA

Like many lean terms we commonly use, they originate in Japan, and we continue to use the

Japanese term here. To be honest, I’m not 100% sure why, but it does make it a little more

interesting and fun.

You don’t have to be doing Lean for very long before you start Hearing Japanese words to

describe things. No doubt you will come across “Kanban, muda and Kaizen” almost immediately.

Depending how far you take your learning, there are many many more terms that are widely

used in the lean community, and for the most part, we all know what they mean.

This article if focusing on 3 words you probably haven’t come across yet. But they are absolute

super powers to have in your arsenal when gong to war with waste.

Lets dive in. The first on is Yokoten. This means “Horizontal information”. Why is this so

important, and how do we do it?

Yokoten is the practice of sharing information across the organization. Generally information

flows up and down to and from managers.

We often forget, that departments laterally can

benefit from our lessons learned as well. The most glaring example of this in the way we teach

lean is improvement videos. During the morning meeting if you are sharing your videos the

office people see shopimprovements, the shop people see office improvements. The

finishing department can learn from the breakout department. It’s viewed as critical for all

departments to share information to spark ideas and learn from each other.

So if you can’t get everyone together at the same time to practice Yokoten at your morning

meeting, devise a for all departments to share their innovations and lessons learned.

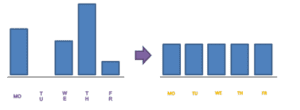

The next is Heijunka: By definition this means “Level your schedule”. One mistake I see all

the time is people get ahold of lean concepts and take them to the extent of what they mean,

without realizing they are guiding principles to help with decisions. An example is Single piece

flow, we hear that and think we need to start building everything one at a time, Don’t do this, the

result will be very bad.

Another one is that lean companies deliver fast. Yes, I would tend to

agree that lean companies generally have better performance than most, but delivering next day

can be detrimental to your factory. When you practise Heijunka, you are collecting orders for a

period of time, then building a level schedule from that. It may look something like this.

Monday orders in: … A – B – C – B – B – C – A

Tuesday orders in:… B – B – C – A – A – C – B

Wednesday orders in: A – C – B – A – B – C – A

Thursday orders in:….A – B – D – A – C – A – B

Friday orders in:……..C – B – A – D – B – C – A

So if you were to build in that order you would be swinging your factory wildly from product to

product, lots of set up and tear down, likely result is a huge lead time. But if you collected

those orders for one week, then released them to the plant, the orders in would be all over the

map, but the plant would see this schedule:

Monday production:…… A – A – A – A – A – A – A

Tuesday production: ……A – A – A – A – A – B – B

Wednesday production: B – B – B – B – B – B – B

Thursday production:…. B – B – B – C – C – C – C

Fridays production:……. C – C – C – C – C – D – D

Even just looking at those two comparisons one calms the mind. But remember: the goal is to

get better, so as your improving, maybe you can reduce that to 4 days, then 3, then 2, and

maybe one day, you can achieve next day delivery. But in the beginning, don’t get to lean to

fast and level that schedule as much as possible without upsetting your customers.

The last word is Hensai. This is a very deeply ingrained practice in the Japanese culture that

we could all benefit from. It means “To reflect with regret”, or I prefer deep reflection.

This is the art of being able to reflect on your own actions and use the reflection to improve for next time.

So it could be to take 5 minutes after hosting a morning meeting and writing down all the things

that didn’t go as you planned. Keep those notes handy, use them when planning your next

meeting. Lynn and I often have the pleasure of speaking at the popular wood shows.

Admittedly, at first, I think we were average at best. But then we started to do the Hensai. Right

after each keynote, we immediately went to a quite place with a pen and paper and wrote down

all the things that went wrong.

Slide 98 didn’t play

When we said “X” we could see people didn’t respond

Audio connection was a struggle in the beginning

Noticed people on their phones during “X” part of the presentation, must have been boring

Internet was lagging while playing videos

And this list started out as a page or more long. Within a few more speaking opportunities we

were able to iron out a lot of the defects and one year we even won the best presentation award

at the Vegas wood show. I didn’t need any more proof than that for the power of Hensai.

What would happen if you could get people in your organization doing Hensai at the end of each

day for 10 minutes? Reflect on what could have went better and how. Then try again tomorrow.

As we dig deeper into our learning from Japan, we start to see how a country with some of the

most expensive labour can compete with China right next door who as some of the cheapest

labour. And for me personally, the lesson always remains, just how sloppy we are here in North

America. I mean that in the nicest possible way, with a hint of tough love.

If you love these articles and the woodworking networks podcast, and want to further your lean

learning, consider following our new Quantum Lean podcast “on the shop floor”. Find it on

YouTube and Spotify.

And if you wanted to learn more about the Japanese principle we learned today and more. Just

txt the word “YOKOTEN” to (226) 971-2144 and someone will contact you shortly.