If you’re the owner of a manufacturing business. You have probably been the

last one out of the shop and as you’re turning off the lights and shutting

everything down, you see your finished product sitting by the shipping door. You

look at it and think to yourself, “it’s five pieces of wood put together into a box

with two doors on it, how could this possibly take so long? “ And if you’re

anything like me the next little bit of math going through your head is how long I

think it would take me, and it’s usually 1/4 of the time the factory is producing it

in, at least in my head.

But why is reality so far apart from what me as an experienced cabinet maker

thinks is possible? I believe it’s because when we think of building something it’s

typically in a perfect world. We’re standing at the bench with all of our tools, we

have all of our parts, and any machines we need are available. So in my head I

slap that cabinet together in 10 minutes hang the doors and I’m done.

But in reality there is a much different picture unfolding. Things we don’t always

see and some very hard to quantify.

I have come to believe that it’s far more difficult to coordinate the building of

products than it is to actually build them.

It’s staggering how complex it is to build a custom kitchen and never ceases to

amaze me that for the most part, us woodworkers figure it out and have happy

customers. Every factory we visit to help kick off their lean journey has similar

problems. Here are five things you can do…..wait, should do to help with this

massively complex business you’ve got yourself into. Albeit none of this will

reduce the complexity, but it will sure help free up some brain power you didn’t

know you were wasting on trivial stuff

1 – get the information as far up the value stream as possible, as soon as possible.

If you’re letting your customers pick colours and handles after you have started

building, you’re setting yourself up for failure. Remember the further up your

value stream you push problems the cheaper they are to solve. Create job

specific checklists (not generic) and have go no go points throughout the

checklist where you have determined if we don’t have this information by this day

the project stops. Being clear and educating your customer on your process will

save you tons of time in the end.

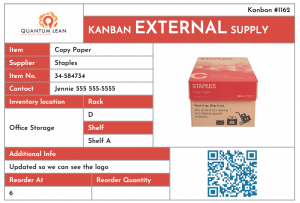

2 – Simplify your purchasing.

There are so many weird and wonderful things that

customers want built into their kitchen that require some purchasing brain power.

Stop wasting your purchaser’s time on trivial stock items. It may seem like no big

deal to order screws, Glue pencils and toilet paper but the reality is those things

take time, time that could be better spent focussing on more difficult tasks. So

get a kanban system in place immediately. I promise you won’t believe the

benefits. Search the archives here on FDMC for our article on Kanban or go to

our blog page at quantumlean.ca

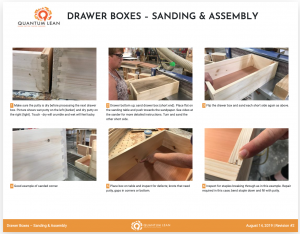

3 – Create standard work documents for all your processes.

I know sounds insaneand like a lot of work. Don’t stop everything to try and accomplish this, just

commit to one or two a day and before you know it they will be everywhere. Your

people are spending their valuable time and brain power explaining things over

and over again to new hires and those poor folks are trying desperately to

remember it. Our little human brains are not designed for remembering, only

creative problem-solving that’s why you find yourself saying “I told them this three

times already!” Save yourself and all the people around you a ton of frustration

and create some standard work documents. From keeping the bathroom clean

to building boxes. Pictures are worth a 1000 words.

4 – Make sure you are measuring!

Measure something, heck measure anything.

Your team needs to know if they are having a good day or a bad day. Count

cabinets per day, pieces per day, dollars per day, or make some kind of point

system. Just try not to get deep into the weeds making it perfect. You’re not using

these numbers to submit your taxes, it’s just a guide to help make decisions on

the shop floor level. And lets everyone know if their improvements are making a

difference. Get everyone behind moving the needle in the right direction, and

they can’t do it without a target.

5 – Training training and training.

This is probably the bane of all of our existence,

and finding the time to do it right seems about as likely as locating Bigfoot. But if

you do a half decent job of your standard work then your training time will be cut

in half and if you want to take that to the next level include videos with your

SOP’s. Don’t think you have to hire Steven Spielberg to get those videos done,

pull out your phone make the video and you’re done. As you start doing this you’ll

see the benefits and like everything else in your factory it will just gradually get

better.

Hope some of these tips help you on your lean journey the fact that you’re

reading this article means you’re in the 2%, remember, if it was easy everyone

would do it. Get out there and make some improvements. If you need any help

advice or just some words of encouragement, visit us at quantumlean.ca and tell

us your story, we’re here to help.