The lesson we’re about to discuss in this article as one I really could’ve used

about 30 years ago when I got started in manufacturing.

A large percentage of businesses grow organically over time, and quite often

there hangs a picture in the office somewhere of the founder working away in a

garage.

And as a business grows, you need people. If you so choose to continue to

grow the business, Sooner or later you will need people to supervise the people,

and depending on how big you get, you may soon find yourself in need of people

to manage those people, and so on and so forth until you have a long list of job

titles like these: team member, team leader, group leader, supervisor, manager,

COO . I think this list could be endless but I’m sure you get the idea.

Now just as important as leading those people, is picking the ones to lead. We

will just use cabinet makers For this example, but it applies to any department,

organization or business for that matter.

I’m generalizing, but I think most of us like to promote from within. Someone

who’s been with the organization a long time, understands the products,

understands the process and can answer just about any question anyone might

have. As you start to fill the organization with people that particular individual

seems like a good fit to be the team leader. So what do we do? We put them in

charge!

Now let’s say they’re doing a satisfactory job. The company keeps growing and

soon you have CNC departments assembly departments, finishing departments,

engineering departments etc. Each one of those departments has a team lead,

but it’s a lot for you to manage so you decide it’s time for a group leader who

effectively is in charge of all of your team leaders. Again, you need someone

who knows the business inside and out and your cabinet maker turned team

lead, who’s been with you for years now seems to fit the bill, after all he’s doing

quite well in his new role. So, once again. We put them in charge!

It feels great to promote people from within, reward them for their hard work and

doing such a good job, it just seems like the right thing to do. But is it?

Let’s keep going shall we. Several years goes by the company continues to

grow and now we need a general manager to oversee all the operations. Guess

who we picked for that job? You got it, your awesome cabinet maker!

Now during his ascent up the ladder there were grumbling’s along the way, but

we chalk that up to people just complaining about their boss, after all the trade-off

of having such a knowledgable person in charge helps you to sleep at night.

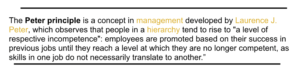

Have you ever heard of something called “the Peter principle“? Here is the

Wikipedia definition:

The Peter principle is a concept in management developed by Laurence J.

Peter , which observes that people in a hierarchy tend to rise to "a level of

respective incompetence": employees are promoted based on their success in

previous jobs until they reach a level at which they are no longer competent, as

skills in one job do not necessarily translate to another.”

So we take someone who’s really good at something and keep moving them up

the ladder until they’re no good anymore, then at that point they never get

promoted again, no one likes to be demoted, so there they are…. Stuck. And

this totally explains how so many bosses are perceived as idiots. Probably they

are not an idiot, they are just one rung on the ladder too high.

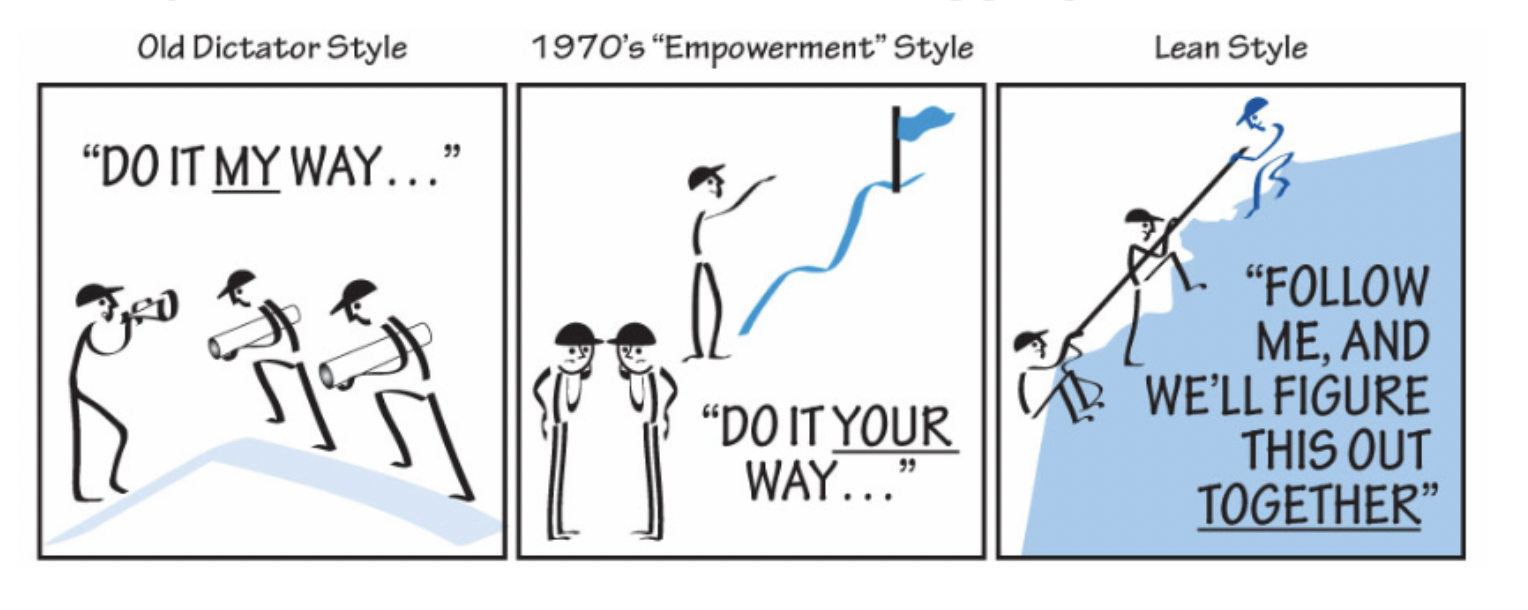

So how do you build these people to lead your lean organization? It’s simple, you

don’t. You cannot train a lean leader, you have to find them. If I had a nickel for

every person I promoted that eventually ended up telling me I didn’t train them,

I’d be rich. A lean leader seeks information, runs face first into a problem and

their first reaction is to read a book on the solution. They are humble, never

satisfied and constantly surprising you. If I had to do it all over again, the #1

quality I would look for would be: someone who is always learning because they

want to.

Please don’t confuse this with you cannot nurture a lean leader, mentor them,

sent them to learn from other organizations. You absolutely should do all of

these things. But you will be wasting your time if they weren’t born with the lean

leader foundation in their soul. They are a special and rare breed, but they are

out there, it just takes some intentional digging to find them.

Here are some tips for a basic structure as your organization grows;

For every 5-10 team members, they should have a team lead, every 5-10 team

leads, there should be a group leader. For every 5-10 group leaders there

should be a manager.

Think of your team members as the surgeons. The ones actually doing the value

added work. Ideally, they should have all their work come to them and they

should be able to just call for help at their station, and help arrives via “the team

leader”. When it comes to improvements, the team members should be

empowered to make on the spot improvements, but if its something that is

technical or may effect other people, that should be brought to the team leader

for approval and consensus.

Team leader role is to support all the activities of the team members. Answer

questions, remove barriers, coordinate the work. A simple goal for the team

leader is to maintain flow and keep everyone at their stations. If someone has to

go wandering around the shop for anything, thats a sign the team lead missed

something. The team leader should also be assistingteam members on their improvements.

Depending on the boundaries set by management, they also wouldbe working closely with

group leaders on the larger process improvements. They should be teaching and

coaching the team members with a keen eye for future team leaders.

Group leader role is setting targets with management and developing plans to

achieve them. Delegating specific tasks to achieve those goals, monitoring team

leaders performance and making course corrections as necessary. Group

leaders should also be removing the barriers preventing team leads for hitting set

targets. A large part of group leaders role is training, coaching and mentoring the

team leaders in all aspects of lean & general manufacturing principles. Their

goal should be to develop future group leaders.

Next time your about to promote someone, make sure they are the character

qualities your looking for, not just the technical skill. A great cabinet maker may

end up being a terrible leader. Remember the “Peter principle” and you will be

well on your way.