Everyones lean journey starts in a different place for a different reason, at a different time.

Regardless of when or why, all the same rules apply, and underlying almost every lean principle

is Standard work.

What is “Standard Work”?

What is “Standard Work”?

In short, it is creating, and documenting a way of doing a task.

The fundamental principle is: every thing is a process, and every

process can be improved. The catch is, despite what

we typically think, we cannot improve a process until it standardized. Sure the owner

or manager can run around showing people how to do it better, but the minute they walk away,

I’d bet its a matter of minutes until workers go right back to what they were doing before, or

even if they continue to try to execute as directed, it won’t be as good as you were hoping.

Let’s quickly examine an operation or process that doesn’t have any standard work. The first

thing you will notice is when people are asked who is good at what, there are usually specialists.

For example, “Joe is our best assembler” or “Mark is fastest saw operator”. This

makes it hard to change tasks because they are specialists. Moving them off of their best position

will have an adverse effect on production, which no one ever wants to risk. Whats the harm in just

leaving people where they are good? Nothing, if they never get bored, never call in sick,

will never retire and don’t mind working 24/7. There is an overwhelming likelihood that you will

have to have another worker doing that task at some point. And this would be the equivalent of

your baker taking the day off, and today its your job to bake the cookies, with no recipe. I

personally will not be first in line to eat your cookies, no offence.

What about the effects of no standards on another 2 very important aspects of the business?

Your process and your customer.

Most of us have more than 2 or 3 steps our products go through before they are ready for

shipment. If we neglect standardization we may find that our processes seem fast one day, and

slow the next. This could be the effects of step 2 having to compensate for something step 1

didn’t quite do it the same as last time. This also can cause excessive inspection of incoming

parts because subsequent stations cannot rely on their parts always being right, or to their

expectations. And they only need to receive bad parts a few times for this paranoia to set in. I

can’t tell you how many factories I have seen this in, and I say, “but the parts look good?” And

the response is something like “well, back in 1976 I had to resend a whole order, I don’t want to

do that again”. Not realizing the excessive inspection is much more laborious than fixing a bad

part every 45 years.

And finally, our customers. Arguably the most important part of the business. They may not

use the word “standard” when they talk about you, but they sure will use words like: reliable,

quality, on time. If every 3rd install or shipment isn’t the same as the rest, to the untrained eye,

they will easily see you don’t have standards. If all your shipments are perfect in the customers

view, the trained eye will likely suspect a lot of over processing in your operation.

So why don’t we all make standard work the back bone of our operations if it’s so important? I

believe mostly because its extremely painful to spend the time to create standards when you

could be doing the actual work. There is also the “I don’t have time” reason. And even if your

one of the few that digs your heels in and starts creating standards, typically they aren’t perfect

the 1st time and the onslaught of revisions is enough to take the wind out of anyones sails. Is

there a quick and easy cure for this, sadly no. It’s like anything, weather its playing the guitar,

going on a diet or starting a work out routine. The results are never on the same day,

the beginning is hard, and the more time you dedicate to it,

more time you dedicate to it,

the easier it becomes. The most important part is to start.

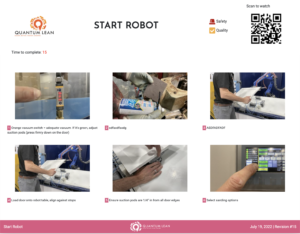

The key to creating and keeping up on your standard work

documents is three fold. Number one is: it must be

simple. Easy to create, easy to edit and easy to go between

revisions. If you’re doing them in a cumbersome fashion,

I promise you will give up on it. If you want to see a great

example of an on-line tool to create standard work, head over to. www.quantumlean.ca

You can see how we make standard work documents a breeze. Second, expect to revise your

first attempts 10 times. Once you start doing this you will see how much information is hidden between

those ears and what we just take for granted. You may get it right in less than 10 tries, but then you

will celebrate a 7 rather than be angry they keep coming back. And last but not least, you must use them.

Every time someone has a question you must resist answering it, and revert back to “what’s the standard say”.

Every time, the moment you don’t is the exact moment people stop looking at them and bog you down

all day with questions. Here are some hints to make life just a bit easier on yourself. 3 simple rules:

BIG pictures

Small amount of writing

Make a video

Now that you’re all excited and ready to start introducing your team to standard work, brace

yourself for a bit of push back from existing employees. Generally it will be along the lines of

“we are custom, you can’t make standards” or “You just want us to be robots”. The response to

we are custom, is Yes you’re correct, we may not be able to standardize everything, but what

things can we do? Then start there. The robot rebuttal is a personal favourite. The response to

that is: Standards actually set you free, I don’t want your creative genius trapped thinking about

how to execute the process, I’d much rather you thinking about how to improve it.

If you’re still not sold on investing in standard work, take a moment and think up 5 of your

favourite big companies and ask yourself, Do they have standards? Then follow up with, would

they still be my favourite company if they didn’t have standards?

If McDonalds had a different tasting Big Mac in each city, would you still eat there? Or if every

Iphone worked just a little different, would you buy it? Could you even scale a business that

didn’t have good standards in place?

Aside from increased production, improved quality and training new people getting much easier

and faster. There in another side benefit you may not have considered, I know it didn’t until it

unfolded in front of me. I can promise 95% of every argument between people in the plant is

because there is no standard. Next time you’re mitigating a dispute ask why 5 times and see if

a standard work document would have prevented the disagreement.

If you need any help creating standard work, I’m here to help. Just remember to start every

sentence with “What’s the standard” and your on your way